Skills

Consulting, Management

Client

John Dibag

Completed Date

20 - 04 - 2021

Location

New York, NY, USA

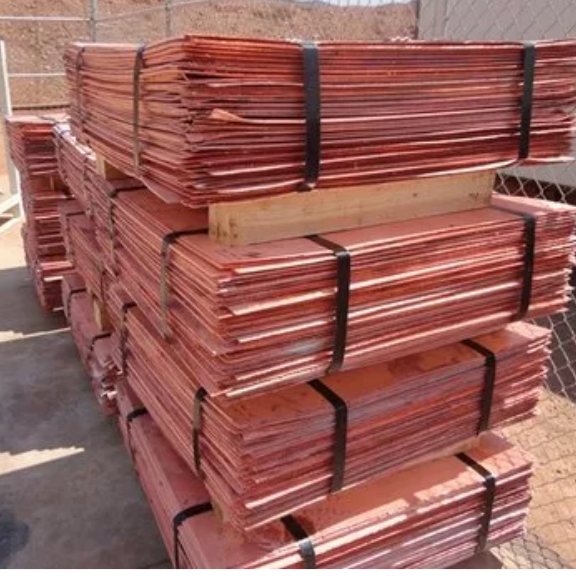

Copper Cathode is a key component in the global metals market. These cathodes are produced through a highly refined electrolytic process, making them pure and ideal for use in various industrial applications. Over time, the technology and methods used in copper cathode production have evolved, improving efficiency and quality. This evolution continues to impact industries ranging from electronics to construction.

The production process of copper cathodes involves a series of stages, including the extraction of raw copper ore, refining through electrolysis, and the final shaping into cathode plates. The quality of the copper cathodes produced is crucial for downstream industries, which rely on their conductivity and purity. Copper is vital for power transmission, electronics, and renewable energy projects, making it a cornerstone of modern infrastructure.

30

+

experience

2070

+

Order Served

15

+

Countries Served

300

+

Happy Customers

Project Goals

The primary goal of this project is to enhance the efficiency and sustainability of copper cathode production. By focusing on advanced refining techniques and improved processes, we aim to reduce costs while increasing the purity and quality of the product.

- Improve electrolytic refining techniques for higher purity

- Reduce environmental impact in the production process

- Increase production efficiency through automation

- Enhance quality control measures in production

- Develop sustainable methods for copper recycling

Over the years, copper cathode production has evolved, with advancements in electrolytic refining and other techniques improving the overall quality of copper. This project will focus on continuing that evolution to meet growing industry demands.

Final Outcome of This Project

The final outcome will be a significant improvement in copper cathode production, with higher purity, reduced environmental impact, and more efficient processes. These advancements will be crucial in meeting the growing demands of industries like electronics and renewable energy.

- Improved copper purity and quality

- More efficient and sustainable production methods

- Reduction in environmental footprint of production

- Advanced automation in the refining process

- Increased production capacity to meet market demand

By focusing on innovative technologies and sustainable practices, this project will help secure a future where copper cathodes meet the high standards required by the global industry.

Work With Us!

Looking to source Copper Cathode?

Partner with us to access premium-grade copper cathodes backed by reliable sourcing and transparent processes. We utilize agile methodologies to ensure efficient logistics, strategic partnerships, and consistent quality for your industrial needs.